Tooling, Design, and Prototyping

At Electro Erosion Specialties, Inc. (EESI) , we have the ability to take your idea and make it a reality. We can assist you with basic design and engineering . Our employees are trained in today's modern software to help turn that thought, drawing on scratch paper, or 2D print into a digital solid file to help you move on to the next step. EESI also has the ability to reverse-engineer a one-of-a-kind part so that it can be re-created as-is or changed/improved.

EESI also has top-of-the-line 3D scanning capabilities. Our 3D scanner can scan your part to .04mm accuracy, ensuring it is as close to the original as possible. We can take any solid object and scan it into the computer, creating an accurate solid file. With this file you have the product necessary to modify or recreate the object you originally scanned. This machine has a wide variety of sizes and accuracies, contact EESI for more info.

We also can assist you if you have made your own solid file and need a prototype. This gives you the ability to hold your creation and possibly test it. In addition to our full machine shop, we have the ability to rapid-prototype parts with our 3D printer. A 3D printer will lay down a thin layer upon thin layer of plastic, building up to a complete part. The machine is driven by the solid file we input into the system. Layer by layer, your part comes to life in plastic. Our 3D printer has an accuracy of .04mm on its finest setting. This gives you a good representation of your final part that allows you to mount and test its shape. 3D printing is an asset in the creation of complex parts and assemblies.

Electric Discharge Machining

EESI was one of the pioneering companies in the Seattle area for EDM. We have years of experience with Wire EDM and Sinker EDM. EESI has upgraded our machines and knowledge of EDM over the years to keep up with technology.

EDM is a process in which electricity is very accurately controlled to burn metal into shapes or cut through metal. With such accurate control over the spark, we are able to the control sizing very accurately. The machines are capable of an unimaginable .00005” accuracy. These machines are used in a wide variety of fields; with their ability to create complex shapes very accurately, they have made a place for themselves in manufacturing for years to come. One of the biggest advantages of EDM is its ability to cut hard materials you could not machine. As long as the material is conductive, we can cut it -- even diamond.

EESI has a few different types of EDM machines. First, we have wire machines that cut with a wire ranging from .003” to .012”. The wire is suspended between two guides vertically cutting through parts. Our machines are 4-axis, which means they have separately controlled heads. This gives us the ability to cut tapers in parts, as well as just vertical parts. This is great in tool and die making and extrusion mold making.

In addition to our wire EDM, we have what is called sinker EDM, or conventional EDM. This machine is similar in layout to a knee mill. It cuts submerged under oil instead of a spindle holding a cutter. It holds an electrode in the shape of whatever you would like to remove. It will travel in whatever direction you like, be it X, Y, or Z. This machine has a wide variety of applications in all fields. The sinker EDMs at EESI are also 4-axis. We have the ability to turn the head as a fourth axis to set angles; we can also spin an electrode and run it similar to a jig grinder. This makes incredibly accurate blind and non-blind holes in all kinds of parts, even after they have been heat-treated.

EESI also has a fast hole, or rapid hole, EDM. This machine uses small electrode and high coolant pressure to put small holes in parts. This machine has the ability to make holes as small as .013”, even in heat-treated material. It goes much faster than conventional EDM, as its sole purpose is hole creation.

Computer Numerical Control (CNC) and Conventional Machining

EESI has a wide variety of machines to help you create exactly what you need and keep the work in-house. We stock limited material right on the shop floor. We cut and prep all material for cutting in-house. This saves on additional operations by our suppliers and keeps cost down.

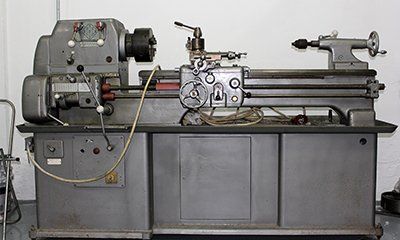

We are able to prep the material to the sizes needed to start machining parts. Once the material is ready to go, we can get it into the shop and start it on one of our types of machines. We have the ability to turn round parts on our lathe. With this machine we can take your round part from print to actual part. It also allows cutting of round electrodes for our EDM machines.

EESI also has a variety of CNC milling machines and the ability to CNC machine 4-axis parts. We also have the ability to do mild high-speed machining. Our-high speed mill has a 10,000 RPM spindle with software that will look hundreds of lines ahead to make sure all operations go together smoothly. This is great for some finish work on lightly heat-treated parts and also for using a small cutter to make fine details.

Surface and Cylingdrical Grinding

EESI has a few different grinding options to fit your needs. We have two different style surface grinders. One is your basic surface grinder that can handle most machine shop tolerances that are required. The second surface grinder is a larger, fine finish grinder. With this grinder we can achieve unmatched finishes and flatness. It is also larger, so you can grind match small parts in one lot.

We also offer fine finish ID/OD grinding. Our cylindrical grinder is designed to grind your smaller-size round parts to the tight tolerance and finishes you might require.

CO2 Laser Marking and Additional Services

Heat Treating

EESI has the ability to heat-treat parts in-house with an electronically controlled furnace. We also have sand/glass bead blasting for scale removal afterward, if needed. We use a steel bag system to protect parts during heat-treat and to reduce scale. We have a hardness tester in-house to make sure the correct hardness required is achieved.

Inspection

EESI has our own in-house inspection department. At EESI we choose not to do all inspection just at the end. We strive to make the best parts possible, so we inspect everything we do as we go along. This ensures rejected parts do not find their way to the end, but rather get removed from production when they fail to measure correctly. This also allows for changes to be made to programs and setups to prevent additional failures. We have inspection machinery, as well as many inspections tools to assist.

Marking

EESI has a few different ways to mark parts. We can mill part numbers and serial numbers into parts. We also have the ability to electric pencil, stamp, or electrode stamp parts. Our preferred method is our in-house C02 laser machine. Our C02 laser is able to not only mark numbers and letters into your parts, but also add a company logo or design. This machine makes a permanent marking on your parts that is legible and stands up to wear and tear. It can also do round parts with the rotary attachment.

Fabrication and Assembly

In many cases, the job is not done just by creating a part. At EESI we have the ability to take it to the very end. We have welding and plasma cutting abilities to aid in fabrication of assemblies. We also have extensive knowledge and experience in the assembly required in Tool and Die making, as well as Mold making. We have the ability to build complete die sets from start to finish, ready to put into your machine. We have a 20-ton press in-house to test die sets. We can also stamp parts for you. We build the molds in-house and work with molding companies to finish the molds with venting modifications and plastics volume ratios.